SMW W Type Rubber Fender

The unique design of SMW W Type rubber fender provides effective energy absorption of excessive impacts. These fenders are quick and simple to install using steel fixing pins that are inserted through the bores of the fender. This enables you to install SMW W Type rubber fenders at a variety of angles around a range of radii.

SMW W Type Rubber Fender Introduction.

SMW W Type Rubber Fender Advantages.

SMW W Type Rubber Fender Application.

SMW W Type Rubber Fender Structure.

SMW W Type Rubber Fender Performance Parameter.

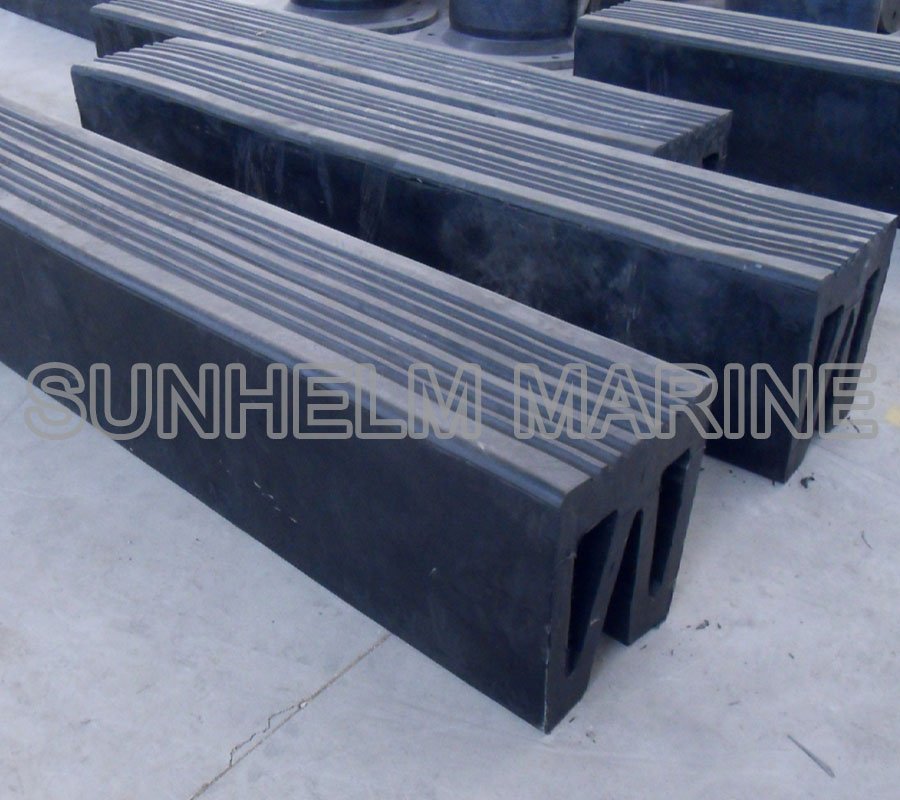

SMW W Type Rubber Fender Introduction

SMW W Type Rubber Fenders are suitable for the most extreme working conditions. The W-type fender is one of the most successful tugboat fenders in the world today. It has a unique "opening" design that makes installation very simple. Flexible legs allow the W-type fender to bend around most hull shapes. Fender is a bumper used to absorb the kinetic energy of a ship or vessel moored alongside a dock, dock wall or other vessel. Rubber fenders are extruded or made in molds. The type of fender that is most suitable for application depends on many variables, including the size and displacement of the ship, maximum allowable stand-off distance, berthing structure, tidal variations and other berth-specific conditions. The size of the fender unit depends on the vessel's berthing energy, which is related to the square of the berthing speed.

SMW W Type Rubber Fender Advantages

Extreme-duty design. Twin-leg attachment. Easy installation. Grooved for extra grip. Fits around tight bends.

SMW W Type Rubber Fender Application

Ocean-going tugs|Icebreakers|Large harbour tugs|Bridge & pile protection

SMW W Type Rubber Fender

SMW W Type Rubber Fender

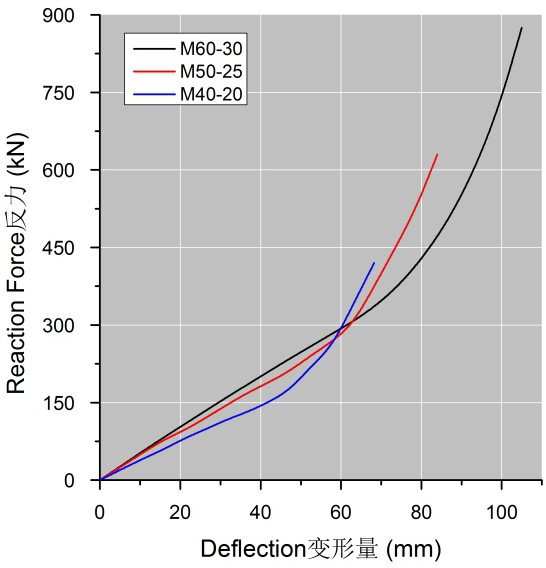

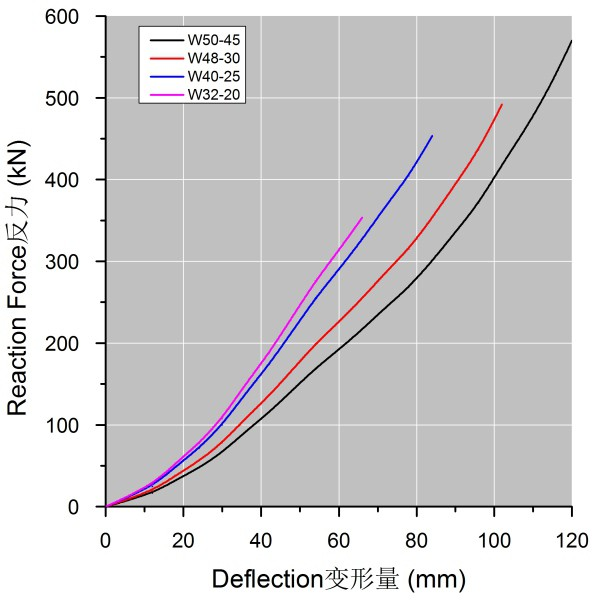

SMW W Type Rubber Fender Performance Parameter

Pin(mm) | Flat Bar | RMax |

Φ25 | 100×20 | 600 |

Φ30 | 120×20 | 800 |

Φ40 | 140×20 | 900 |

Φ40 | 150×20 | 1000 |

Type(mm) | A | B | C | D | E | F | K | LMax | weight(kg/m) |

W32-20 | 320 | 200 | 280 | 180 | 100 | 67 | 50 | 3000 | 59 |

W40-25 | 400 | 250 | 350 | 220 | 110 | 75 | 55 | 3000 | 88 |

W48-30 | 480 | 300 | 420 | 270 | 145 | 90 | 65 | 3000 | 130 |

W50-45 | 500 | 450 | 420 | 270 | 145 | 100 | 75 | 3000 | 192 |

Pin(mm) | Flat Bar | RMax |

Φ20 | 100×16 | 440 |

Φ24 | 125×20 | 550 |

Φ30 | 150×20 | 650 |

Φ40 | 150×20 | 1000 |

Type(mm) | A | B | C | D | E | F | K | LMax | weight(kg/m) |

M40-20 | 400 | 200 | 40 | 23 | 50 | 150 | 3000 | 60 | 59 |

W50-25 | 500 | 250 | 50 | 27 | 60 | 190 | 3000 | 95 | 88 |

M60-30 | 600 | 300 | 60 | 33 | 70 | 230 | 3000 | 140 | 130 |

W50-45 | 500 | 450 | 420 | 270 | 145 | 100 | 75 | 3000 | 192 |