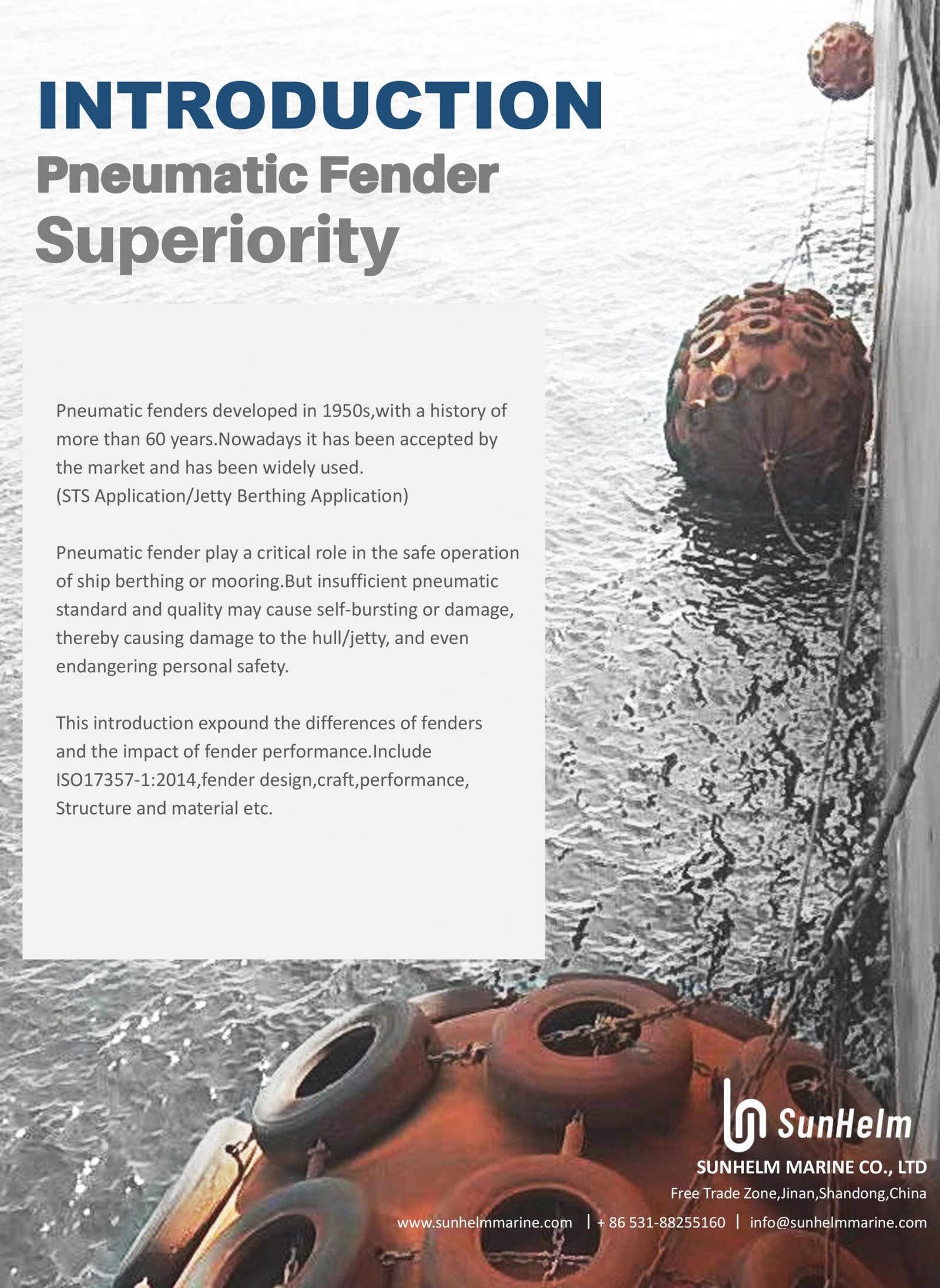

Pneumatic Fenders

Pneumatic fenders are the most commonly used ship-to-ship transfer fenders and are also used as vessel-to-berth at dock/jetties.

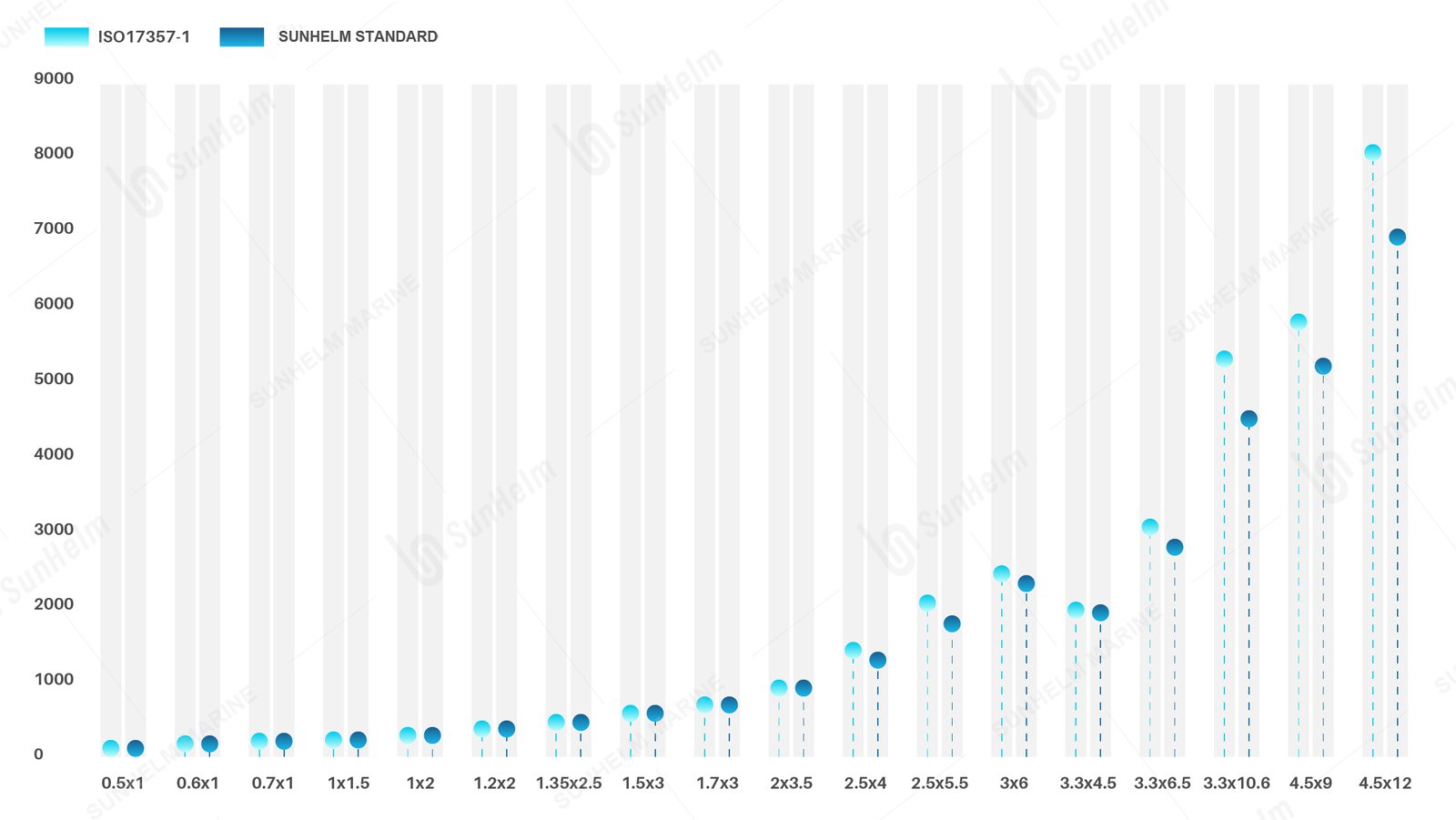

To exceed the performance of ISO17357 standard.

Excellent energy absorption and reaction force.

Use cases of Pneumatic fenders in harsh environments.

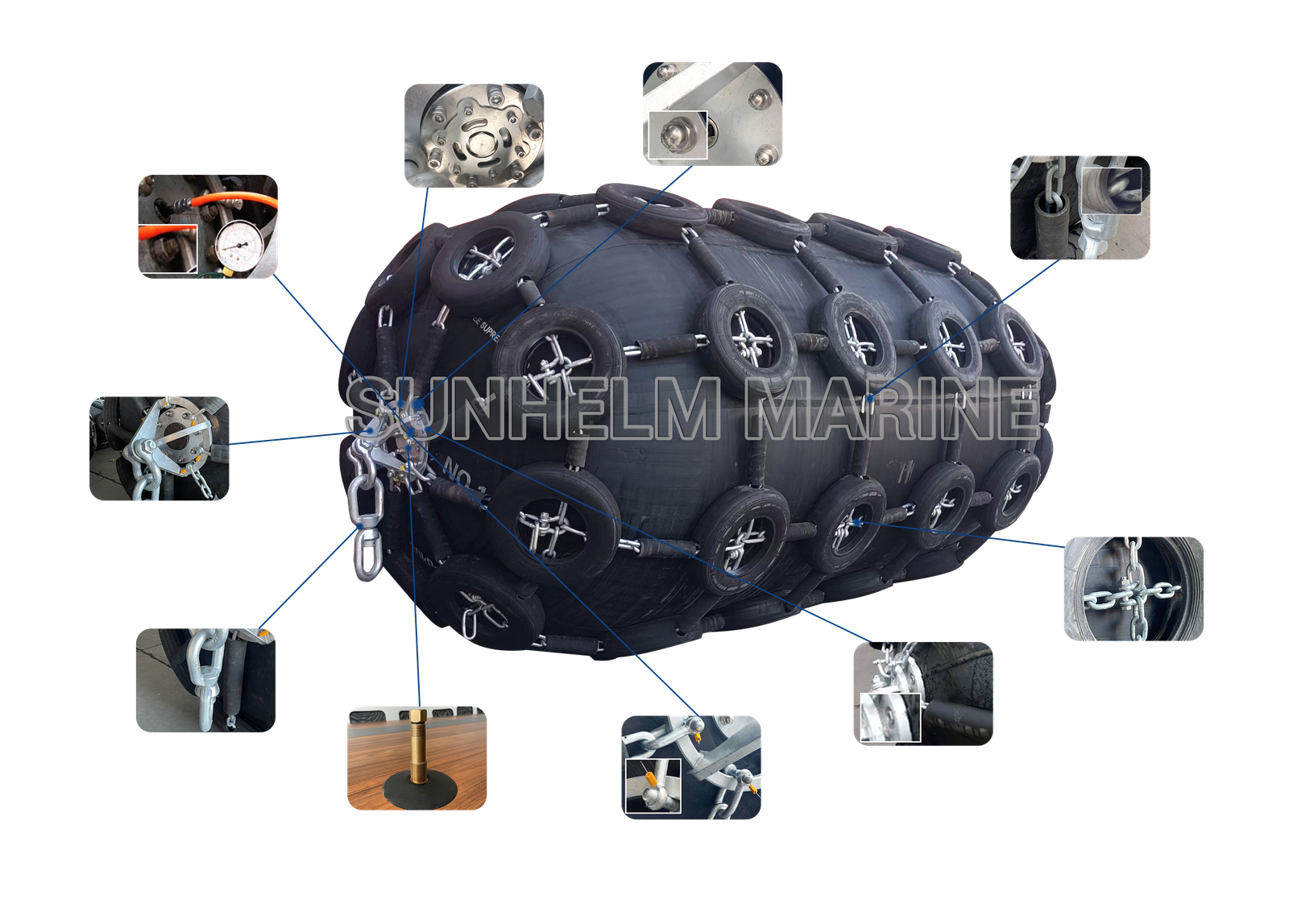

No detail is spared with our Pneumatic Fender.

Pneumatic Fender Types

Chain&tyre Net Type Pneumatic Fender

Sling Type Pneumatic Fender Rope Net Type Pneumatic Fender Rib Type Pneumatic Fender Grey Type Pneumatic Fender Red Type Pneumatic Fender

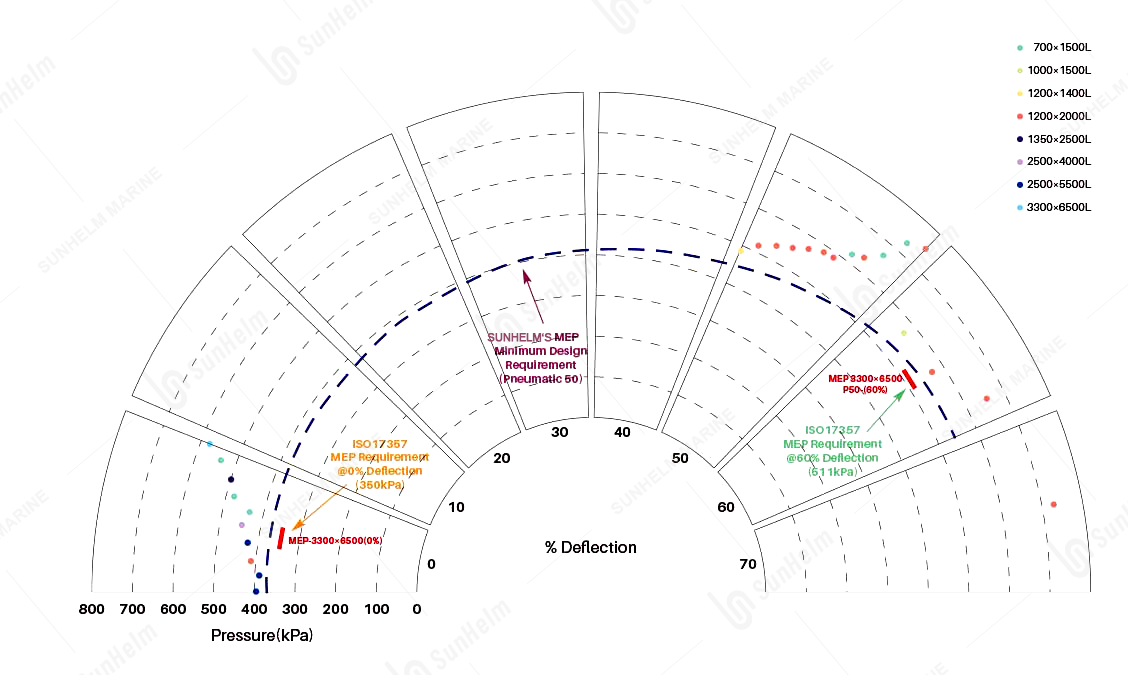

To exceed the performance of ISO17357 standard

The safety factor adopted in the design of this fender is based on accepted theory and has been proven by extensive experimentation.Operational experience over a long period of time attests to its high safety and reliability,and hydraulic pressure tests have proven the strength to be suitable.

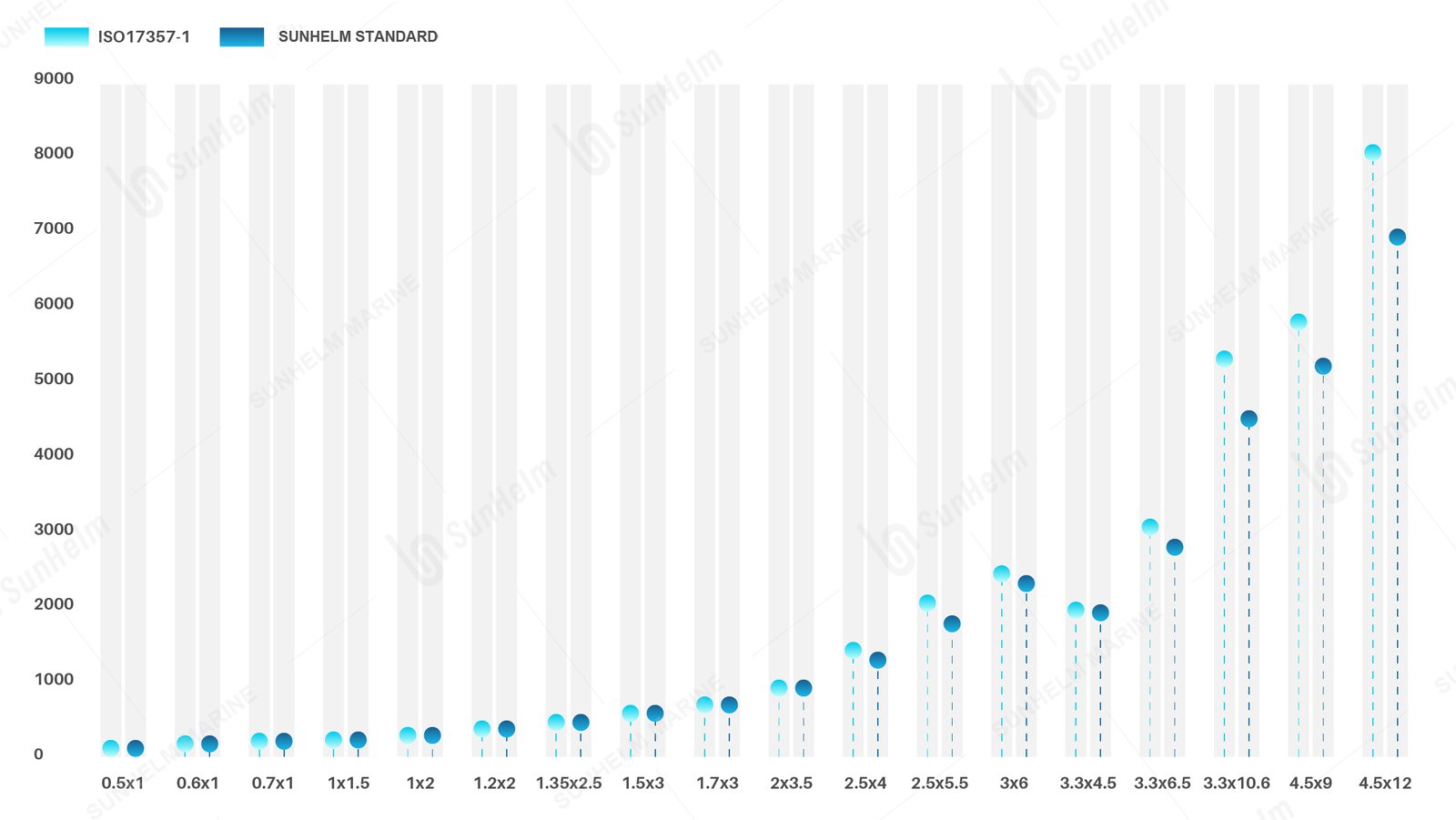

Excellent energy absorption

The energy absorption of SUNHELM pneumatic fender not only comply the standard with ISO17357, but after deep optimization and testing of the quality of fender, energy absorption performance exceeds the standard requirement of ISO17357, which can achieve the best energy absorption effect by fender and fully protect it.

Excellent reaction force

On the basis of better than ISO17357 energy absorption performance,after deep optimization and testing of fender quality, the reaction force performance is even better than ISO17357.

Pneumatic Fender Compression experiment

STS operation (Large Ship) apply with D1500mm*L3000mm SUNHELM pneumatic fender.Application environment is bad,strong wind and waves.Fender compression over 70% still keep superior performance to fully protect ship,not burst.

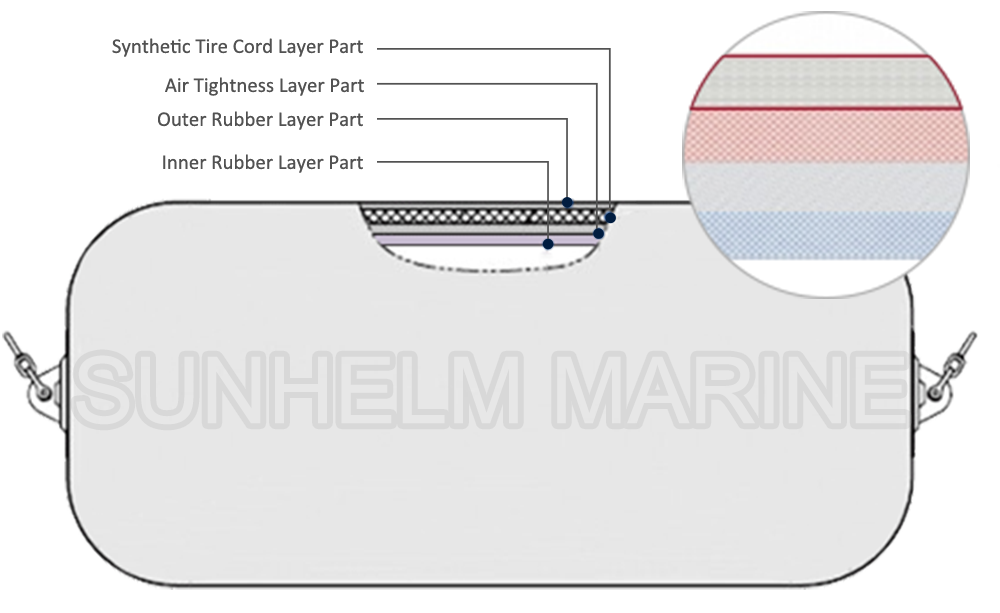

Outer Rubber Layer Part

I Mechanical protection (Friction) I Chemical Resistance (Environment) I Energy dissipation

Synthetic Tire Cord Layer Part

I Carry load of membrane force I keep the geometry stable

Rubber Matrix Part

I Adhesion to reinforcement material I Distance layer of fabric plies I Shearing force loading

Air Tightness Layer Part

I Strengthen air tightness I Reinforces rubber & tire cord plies

Inner Rubber Layer Part

I Pressure transfer I Ensure air tightness I Provides chemical resistance

Pneumatic Fender Construction

-e1680492079619.png)

Rubber Sleeve Enough Thickness

Enough thickness ,extended service life.Rubber sleeve with synthetic tire cord reinforcement.Rubber sleeve is used to prevent the friction between chain and fender. When rubber sleeve fails, the chain begins to rub against the fender, thereby reducing the fender service life.

-e1680491864735.png)

Chain ,Shackle and Tire Net Pneumatic Fenders

Chain thicker diameter, short length, close arrangement,Stronger bearing capacity. Shackle Intersection of horizontal and vertical chains with shackle design. Chain Net separated chain design,connect with shackle,chain towing/hanging force is even.

.png)

Safety Valve For Safer of Big Size Pneumatic Fenders

Excellent larger structural design, efficient and fast to release internal pressure ,Ensure fender safety completely.Self-developed and designed safety valve has a number of unique patents, as a vital insurance measure which can quickly and accurately release pressure in emergency situations.

-e1680492326873.png)

High Quality Flange Cage Design

The function of CTN is to protect the fender and prolong the service life, and the coverage density should reach 70% or more. The CTN bears the hanging/towing force and the CTN also a part with many details.Therefore, it is very important to scientifically evaluate the performance and design of CTN.

We have stock of pneumatic fenders in common sizes of STS.

Want to ship quickly?

No problem!

info@sunhelmmarine.com

+86 (0)531 88255160

WhatsApp: +8615668327389

Pneumatic Fender Structure

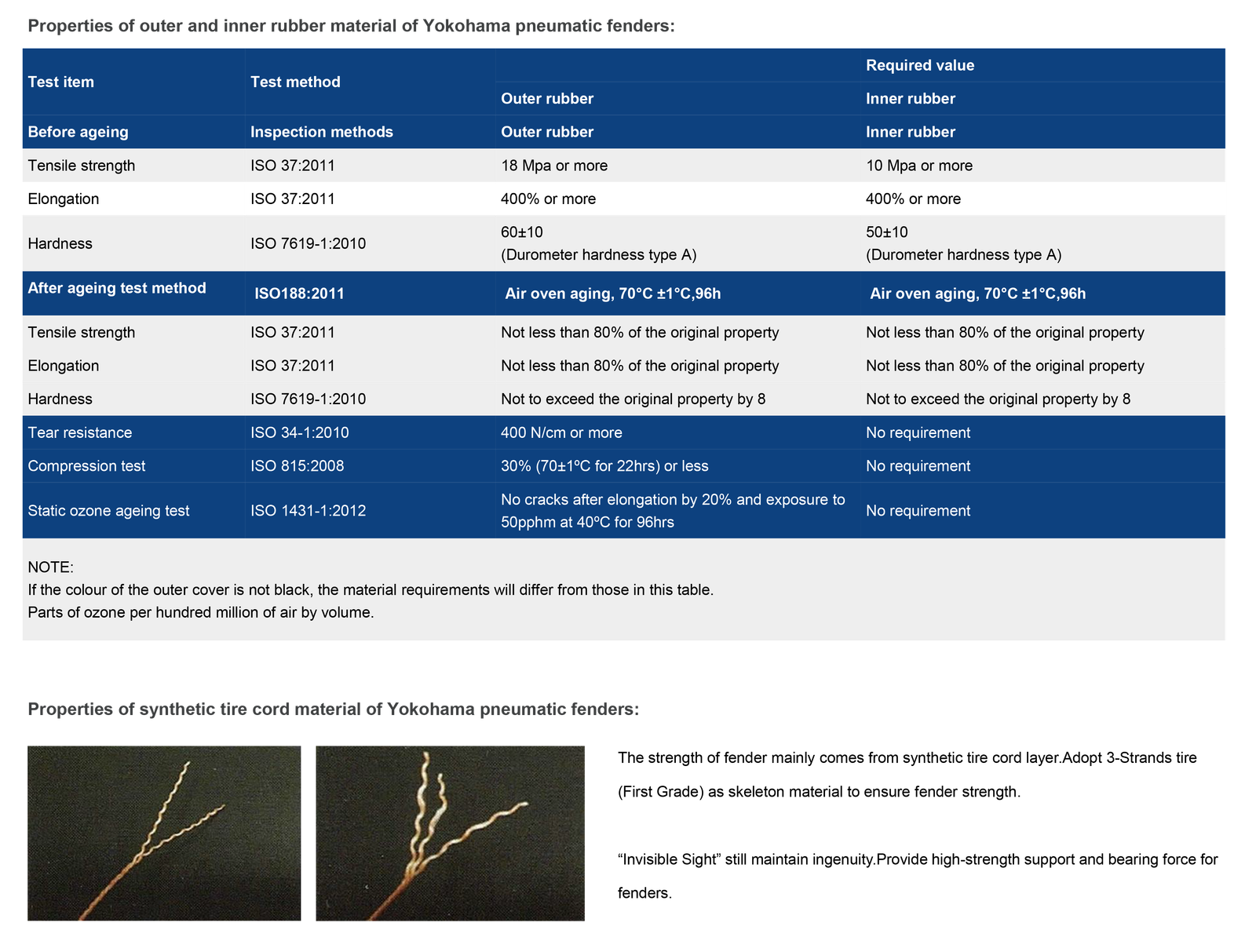

- MATERIAL PROPERTIES

- PNEUMATIC FENDER 50 (METRIC) STANDARD SIZES

- PNEUMATIC FENDER 80 (METRIC) STANDARD SIZES

Yokohama pneumatic fender 50 (metric) standard sizes

Technical performance table

Nominal size diameter x length mm x mm | Initial internal pressure kPa | Guaranteed energy absorption (GEA) kJ | Reaction force at GEA kN | Hull pressure at GEA kPa | Safety valve setting pressure kPa | Testing pressure kPa | Approx. fender body weight kg | Approx. weight of net kg | Weight of sling type (type II) kg |

| 500 x 1000 | 50 | 6 | 64 | 132 | - | 200 | 22 | 160 | 32 |

| 700 x 1500 | 50 | 17 | 137 | 135 | - | 200 | 45 | 185 | 55 |

| 1000 x 1500 | 50 | 32 | 182 | 122 | - | 200 | 73 | 250 | 98 |

| 1000 x 2000 | 50 | 45 | 257 | 132 | - | 200 | 88 | 385 | 113 |

| 1200 x 2000 | 50 | 63 | 297 | 126 | - | 200 | 131 | 430 | 156 |

| 1350 x 2500 | 50 | 102 | 427 | 130 | - | 200 | 200 | 675 | 240 |

| 1500 x 3000 | 50 | 153 | 579 | 132 | - | 200 | 250 | 795 | 290 |

| 1700 x 3000 | 50 | 191 | 639 | 128 | - | 200 | 290 | 830 | 330 |

| 2000 x 3500 | 50 | 308 | 875 | 128 | - | 200 | 405 | 1165 | 465 |

| 2000 x 4500 | 50 | 418 | 1188 | 137 | - | 200 | 480 | 1700 | 540 |

| 2500 x 4000 | 50 | 663 | 1381 | 137 | 175 | 250 | 902 | 1745 | 1080 |

| 2500 x 5500 | 50 | 943 | 2019 | 148 | 175 | 250 | 1090 | 2765 | 1320 |

| 3300 x 4500 | 50 | 1175 | 1884 | 130 | 175 | 250 | 1460 | 2650 | 1840 |

| 3300 x 6500 | 50 | 1814 | 3015 | 146 | 175 | 250 | 1870 | 3840 | 2250 |

| 3300 x 10,600 | 50 | 3067 | 5257 | 158 | 175 | 250 | 2560 | 6755 | 3060 |

| 4500 x 9000 | 50 | 4752 | 5747 | 146 | 175 | 250 | 3940 | 7365 | - |

| 4500 x 12,000 | 50 | 6473 | 7984 | 158 | 175 | 250 | 4790 | 9875 | - |

Note:

- Figures on the table comply with ISO 17357

- Weight of fender body and net may vary ±10%.

- Special sizes are available on request simply

Yokohama pneumatic fender 80 (metric) standard sizes

Technical performance table

Nominal size diameter x length mm x mm | Initial internal pressure kPa | Guaranteed energy absorption (GEA) kJ | Reaction force at GEA kN | Hull pressure at GEA kPa | Safety valve setting pressure kPa | Testing pressure kPa | Approx. fender body weight kg | Approx. weight of net kg | Weight of sling type (type II) kg |

| 500 x 1000 | 80 | 8 | 85 | 174 | - | 250 | 24 | 160 | 34 |

| 700 x 1500 | 80 | 24 | 180 | 177 | - | 250 | 47 | 185 | 57 |

| 1000 x 1500 | 80 | 45 | 239 | 160 | - | 250 | 76 | 250 | 101 |

| 1000 x 2000 | 80 | 63 | 338 | 174 | - | 250 | 92 | 385 | 117 |

| 1200 x 2000 | 80 | 88 | 390 | 166 | - | 250 | 135 | 430 | 160 |

| 1350 x 2500 | 80 | 142 | 561 | 170 | - | 250 | 205 | 675 | 245 |

| 1500 x 3000 | 80 | 214 | 761 | 174 | - | 250 | 277 | 795 | 317 |

| 1700 x 3000 | 80 | 267 | 840 | 168 | - | 250 | 316 | 830 | 356 |

| 2000 x 3500 | 80 | 430 | 1150 | 168 | - | 250 | 413 | 1165 | 473 |

| 2000 x 4500 | 80 | 584 | 1560 | 179 | - | 250 | 488 | 1700 | 548 |

| 2500 x 4000 | 80 | 925 | 1815 | 180 | 230 | 300 | 1010 | 1745 | 1190 |

| 2500 x 5500 | 80 | 1317 | 2653 | 195 | 230 | 300 | 1230 | 2765 | 1460 |

| 3300 x 4500 | 80 | 1640 | 2476 | 171 | 230 | 300 | 1720 | 2650 | 2090 |

| 3300 x 6500 | 80 | 2532 | 3961 | 191 | 230 | 300 | 2200 | 3840 | 2570 |

| 3300 x 10,600 | 80 | 4281 | 6907 | 208 | 230 | 300 | 3030 | 6755 | 3520 |

| 4500 x 9000 | 80 | 6633 | 7551 | 192 | 230 | 300 | 4380 | 7365 | - |

| 4500 x 12,000 | 80 | 9037 | 10490 | 202 | 230 | 300 | 5330 | 9875 | - |

Note:

- Figures on the table comply with ISO 17357

- Weight of fender body and net may vary ±10%.

- Special sizes are available on request simply

What can

we do for you?

Find us to know more

Find us to know more

Find us to know more

Sunhelm has independently developed and produced pneumatic rubber fenders for 15 years. The production technology is mature, the technical research and development team is perfect, and the materials and production methods are constantly updated. It is already a leading manufacturer and supplier of pneumatic fenders in China.

Many export countriesSunhelm has been deeply involved in the international market, and yokohama pneumatic fenders have been sold to 27 countries around the world including Russia, Brazil, Indonesia, Malaysia, Germany, Panama, and the United Arab Emirates. The customer complaint rate is only 1%.

Higher safety factorSunhelm’s pneumatic Yokohama fender fully meets the ISO17357 standard, uses a stronger cord layer, and has a safety factor of 7 times. You can buy it more at ease.

Find us to know more

A ship-to-ship (STS) transfer operation is the transfer of cargo between seagoing ships positioned alongside each other, either while stationary or underway. Cargoes typically transferred via STS methods include crude oil, liquefied gas (LPG or LNG), bulk cargo and petroleum products. For ship-to-ship operations, usually 3-5 pcs pneumatic fenders are put between two ships, if transfer oil or liquefied gas, STS Hoses will be used to connect two ships cargo oil systems or gas tanks. Pneumatic fenders usually are anchored by mooring ropes to one ship’s main deck bollards.

Heavy duty design - Safety factor of pressure strength is more than five times of the operating pressure.

No permanent deformation - Helix wire free construction - deformation shall not remain permanently even though hoses get kinked by rough bending and deformation by slight vacuum during operation.