Floating Airbags

The floating airbag developed and produced by SunHelm Marine mainly includes: light ducy floating airbag and heavy ducy floating airbag.

Light duty floating airbags are mainly used in short-term projects and are suitable for projects with low buoyancy.

Heavy duty floating airbags are mainly used in longer-term projects and heavy-duty projects with high buoyancy.

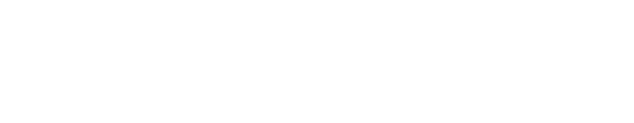

- Latent Arresting Bag.

- Vessel float-up tool.

- Pipeline and cable laying.

- Floating assistant tools.

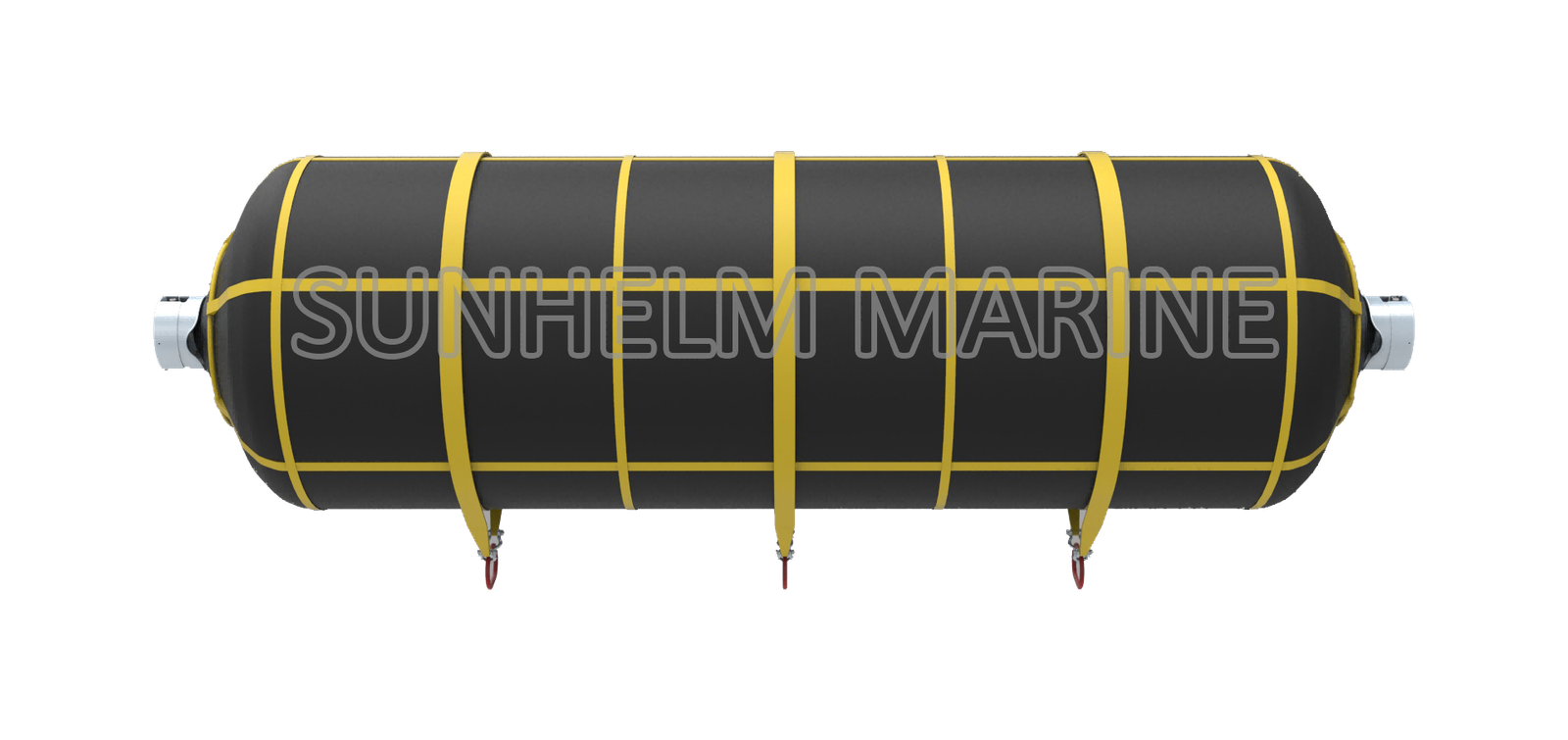

Light Duty Floating Airbag

- Sufficient buoyancy capacity: 1-200 tons/piece.

- It is suitable for various shallow water salvage and buoyancy projects.

- Good puncture resistance and abrasion resistance and good air tightness.

- Durable, versatile and easy to operate.

- Unique nylon wrapping net prevents the airbag from slipping off and restores airbag during offshore applications.

- ISO9001:2008 by BV certificate.

- Comply with IMCA D 016 Rev 3 - June 2007 guidelines.

- Safety valves at both ends to avoid over-pressure.

- Equipped with all the necessary hardware and ready for immediate application.

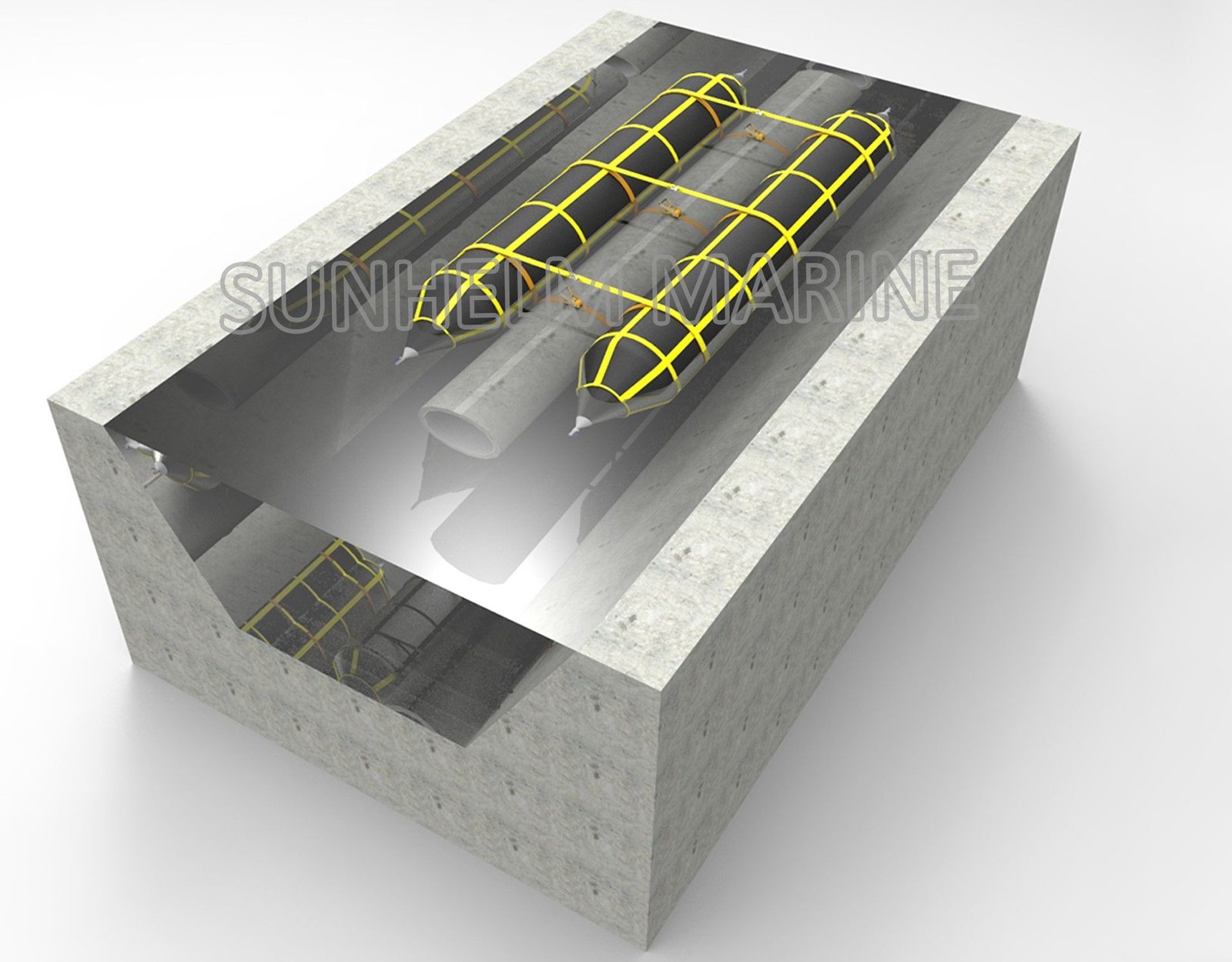

Heavy Duty Floating Airbag

- The rubber cylinder is flexible, allowing for a vacuum state and easy folding. It occupies minimal space, is lightweight, and facilitates transportation.

- With a material density of around 1.3, the float's weight in water is significantly lighter than in air, making it convenient for underwater installation.

- High overall buoyancy efficiency results in low unit buoyancy costs, providing the float with a competitive advantage in terms of unit buoyancy costs.

- The heavy-duty pneumatic float, with a net sleeve, enables force transmission at mooring points.

- It boasts a rational structure, easy installation, and reliable performance.

- The float has an inflation control device for leak prevention, automatic air release, emergency release, and valve protection, ensuring internal pressure safety.

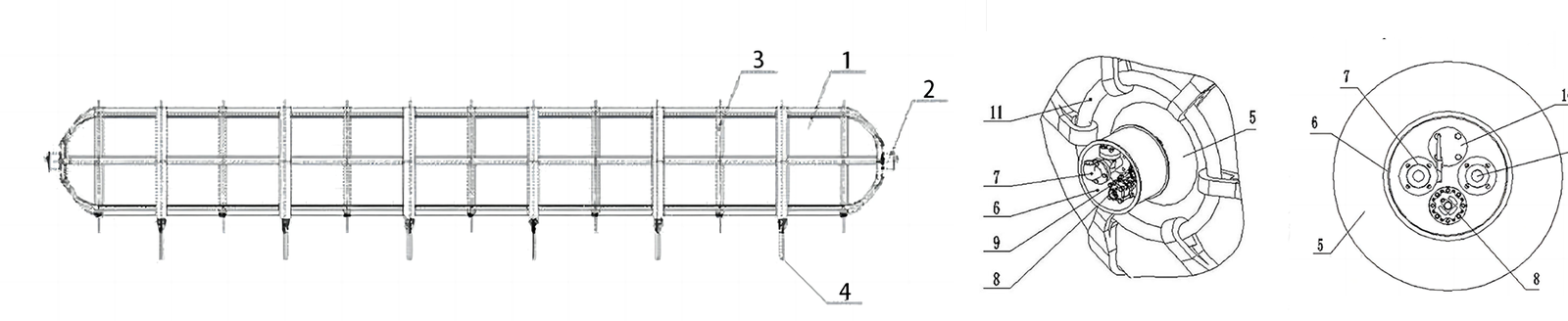

Light Duty Floating Airbag Construction

1. Floating body 2. Outer rubber layer 3. Skeleton layer 4. Inner rubber layer 5. Air valve 6. Conical compression sleeve 7. Locking nut 8. Traction frame 9. First bolt 10. Inflation and deflation bend pipe 11. Quick-release buckle 12. Ball valve 13. Second bolt

Heavy Duty Floating Airbag Construction

1.Floating body 2.Inflation control valve assembly 3.Net sleeve 4.Mooring rope 5.Transition cover 6.Protective cover 7.Inflation check valve 8.Shut-off valve 9.Safety valve 10.Reserved opening 11.Fastening ring

Air Lifting Bags

Air Lifting Bags are one kind of inflatable buoyancy bags made of Heavy Duty PVC coating fabric material.

SunHelm Marine manufacture many different types of underwater lifting bags, which includes parachute type open bottom lift bags, cylindrical shape enclosed type underwater lift bags, pillow type inflatation bags, elongated pontoon… They mainly use for commercial diving, sunken boat lift, marine salvage and re-floatation, pipeline or ship buoyancy support. All lifting bags are manufactured and rigorously examined in full compliance with IMCA D-016. SUNHELM underwater lifting bags are mainly used by international offshore and marine contractors.

Floating Airbag Technical Service

SunHelm Marine has been deeply involved in the marine industry for more than 20 years. In the field of floating and sinking salvage, we have a professional technical team that can provide "one-stop" services according to customers' projects, formulate optimal solutions, and provide high-quality on-site guidance services.

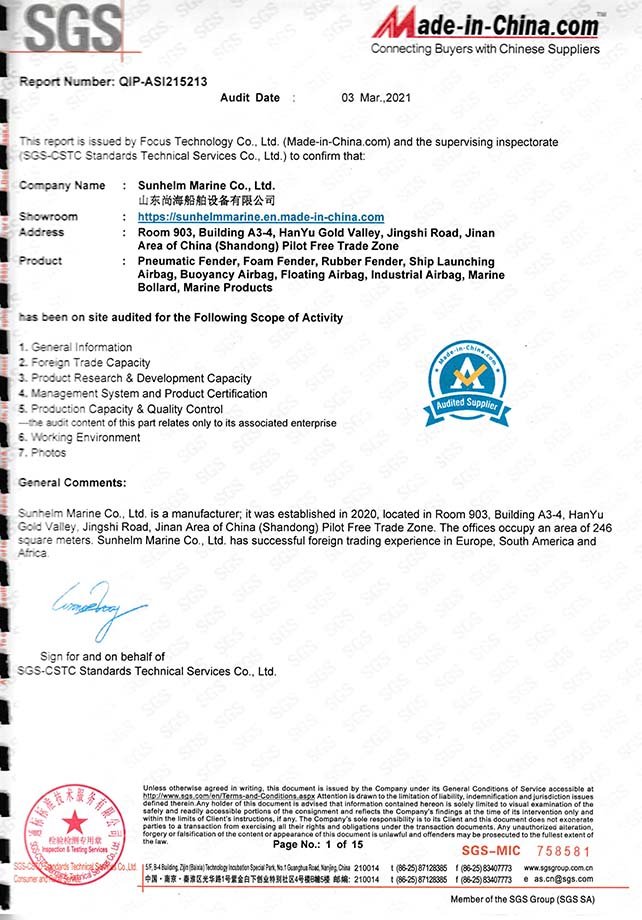

International Leading Buoyancy Airbag Manufacturer

SunHelm Marine Co., Ltd. is a Chinese manufacturer specializing in maritime products. SunHelm Marine currently has several large-scale modern factories and R&D centers. SunHelm Marine mainly produces pneumatic fenders, marine rubber fenders, foam fenders, hydro-pneumatic fenders, marine airbags, marine salvage airbag, caisson moving airbags and other products.

Based on ship industry chain, SunHelm Marine has expanded its market layout, main business involves ship mooring and berthing, marine engineering, port construction and other fields. SunHelm provides customers with systematic, comprehensive and creative services.

After nearly 20 years of development, product and technology applications have covered more than 80 countries and regions in 7 continents, NANHAI became the well-known brand in the world.

Our Products

We are in the business of developing high performance marine rubber protections. According to 20 years researching and developing, SunHelm Marine has abundant experiences in custom designing marine fenders and airbags to meet specific application needs. We are pride with ourselves on our quality and stand behind our products.