SFA Cell Rubber Fender

SFA Cell Rubber Fender is a well established rubber fender type,with a hollow cylindrical body and fully rubber-embedded mounting flanges.

SFA Cell Rubber Fender Introduction.

SFA Cell Rubber Fender Advantages.

SFA Cell Rubber Fender Application.

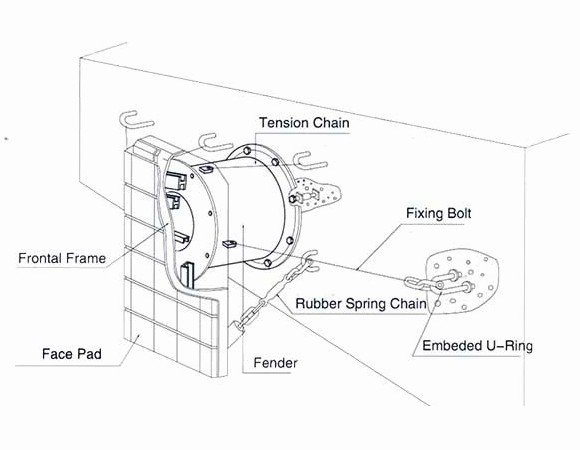

SFA Cell Rubber Fender Structure.

SFA Cell Rubber Fender Performance Parameter.

SFA Cell Rubber Fender Introduction

SFA Cell Rubber Fender is designed to deflect in an axial direction up to 52,5% (design deflection). SFA Cell Fenders have a very long track record and remain popular because of their simplicity, high performance and strength. SunHelm’s SFA Cell Rubber Fenders come in a wide range of standard sizes and are interchangeable with many, older marine cell fender types.Heights between 400 and 3,000 mm.

SFA Cell Rubber Fender Advantages

Easy assembly & installation. Good shear force resistance. Low reaction force,high energy absorption. Can support large panels. Strong, well-proven design. Ideal for low hull pressure systems. Very robust . Cost-effective:large footprint leads to a good load distribution over the front panel,which results in a lighter panel construction.

SFA Cell Rubber Fender Application

Bulk terminals|Oil and LNG facilities|Container terminals|Ro-Ro and cruise terminals|Offshore platforms|Multi-user berths

SFA Cell Rubber Fender

SFA Cell Rubber Fender

SFA Cell Rubber Fender

SFA Cell Rubber Fender

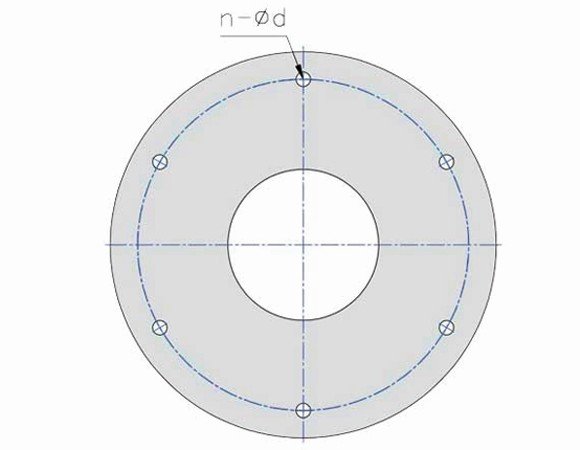

SFA Cell Rubber Fender Structure

SPEC. (mm) | H | T | ΦW | CB | CD |

500H | 500 | 25 | 550 | 650 | 32 |

630H | 630 | 30 | 700 | 840 | 39 |

800H | 800 | 30 | 900 | 1050 | 40 |

1000H | 1000 | 35 | 1100 | 1300 | 47 |

1150H | 1150 | 40 | 1300 | 1500 | 50 |

1250H | 1250 | 45 | 1450 | 1650 | 53 |

1450H | 1450 | 47 | 1650 | 1850 | 61 |

1600H | 1600 | 50 | 1800 | 2000 | 61 |

1700H | 1700 | 55 | 1900 | 2100 | 66 |

2000H | 2000 | 55 | 2000 | 2200 | 74 |

2250H | 2250 | 60 | 2300 | 2550 | 74 |

2500H | 2500 | 70 | 2700 | 2950 | 74 |

3000H | 3000 | 75 | 3150 | 3350 | 90 |

*Fender anchors / head bolts indicated are based on a particular grade of steel. Please contact our local office for precise size, material and type for different grades of fenders pertaining to the project requirements. | |||||

We will provide you with the best quality products and the most competitive prices!

Want to ship quickly?

No problem!

info@sunhelmmarine.com

+86 (0)531 88255160

WhatsApp: +86 13573172195

SFA Cell Rubber Fender Performance Parameter

SPEC.(mm) | 500H | 630H | 800H | 1000H | 1150H | 1250H | 1450H | 1600H | 1700H | 2000H | 2250H | 2500H | 3000H | ||

PERFORMANCE | |||||||||||||||

RE | 52.5% | R | 182 | 290 | 464 | 737 | 975 | 1153 | 1551 | 1885 | 2131 | 2941 | 4145 | 5118 |

|

E | 40 | 80 | 163 | 324 | 492 | 632 | 987 | 1326 | 1591 | 2591 | 4095 | 5618 |

| ||

55.0% | R | 210 | 309 | 493 | 784 | 1037 | 1125 | 1649 | 2007 | 2266 | 3136 | 4406 | 5441 |

| |

E | 43 | 85 | 173 | 343 | 521 | 669 | 1045 | 1405 | 1685 | 2743 | 4337 | 5949 |

| ||

RS | 52.5% | R | 162 | 258 | 412 | 655 | 865 | 1022 | 1376 | 1676 | 1832 | 2619 | 3679 | 4543 |

|

E | 36 | 72 | 145 | 287 | 437 | 561 | 876 | 1177 | 1414 | 2300 | 3628 | 4987 |

| ||

55.0% | R | 187 | 274 | 437 | 696 | 920 | 1087 | 1464 | 1781 | 2012 | 2783 | 3911 | 4829 |

| |

E | 38 | 76 | 153 | 304 | 463 | 594 | 928 | 1247 | 1495 | 2435 | 3848 | 5280 |

| ||

RH | 52.5% | R | 140 | 224 | 355 | 567 | 750 | 886 | 1193 | 1453 | 1640 | 2270 | 3188 | 3937 | 5687 |

E | 30 | 62 | 125 | 249 | 379 | 486 | 760 | 1020 | 1221 | 1994 | 3150 | 4322 | 7456 | ||

55.0% | R | 160 | 237 | 378 | 603 | 798 | 942 | 1269 | 1544 | 1743 | 2413 | 3390 | 4182 | 6619 | |

E | 32 | 67 | 132 | 264 | 401 | 516 | 804 | 1080 | 1300 | 2111 | 3336 | 4576 | 7521 | ||

RO | 52.5% | R | 108 | 172 | 275 | 436 | 578 | 682 | 918 | 1120 | 1262 | 1746 | 2454 | 3028 | 4314 |

E | 23 | 47 | 96 | 191 | 295 | 375 | 585 | 786 | 945 | 1535 | 2425 | 3330 | 5676 | ||

55.0% | R | 125 | 182 | 292 | 463 | 614 | 725 | 976 | 1189 | 1342 | 1856 | 2607 | 3220 | 5099 | |

E | 25 | 50 | 102 | 203 | 309 | 396 | 619 | 832 | 997 | 1624 | 2566 | 3520 | 6028 | ||

RL | 52.5% | R | 86 | 138 | 211 | 349 | 462 | 546 | 735 | 894 | 1009 | 1398 | 2085 | 2574 | 3677 |

E | 18 | 38 | 75 | 153 | 233 | 299 | 468 | 628 | 753 | 1221 | 2060 | 2826 | 4897 | ||

55.0% | R | 99 | 147 | 225 | 372 | 491 | 581 | 781 | 950 | 1073 | 1485 | 2216 | 2737 | 4217 | |

E | 19 | 40 | 78 | 163 | 247 | 316 | 495 | 665 | 798 | 1299 | 2180 | 2992 | 5193 | ||

RE: Extreme high Reaction Force RS: Super high Reaction Force RH: High Reaction Force RO: Standard Reaction Force RL: Low Reaction Force | R: Reaction Force E: Energy Ab sorption Rated Deflection: 52.5% Maximum Deflection: 55% Performance tolerance: ±10% | ||||||||||||||