Foam Filled Fender

Foam Filled Fenders is a floating type compression fender that used lightweight and highly elastic EVA foam as a cushioning medium, The floating foam fender is very safe to use, and there is no risk of blasting. Even if the outer skin is damaged, it will not sink. It can still maintain basic functions until you can repair it.

During the ship-to-ship operations, Foam fender could against a quay wall with deployed or suspended. Whether in the site with small or large tidal, Collision Blocker could adapt to the different working environments as soon.

SunHelm’s fenders are gentle on soft-skinned ships because the hull pressures are pretty low. It makes the cover skin become powerful and non-marking even against with white-hulled yachts and cruise liners.

- Cruise ships.

- Container vessels.

- RoRo and ferries.

- Oil and gas tankers.

- Ship-to-ship transfers.

Foam Filled Fender Characteristics

- Very low hull pressure.

- Low reaction and high energy.

- Non-marking Polyurethane skin.

- Virtually indestructible, won't be burst.

- Unsinkable even if damaged.

- Anti-UV, Anti-acid, alkali and salt.

- Low maintenance cost.

- Wide range of standard & custom sizes.

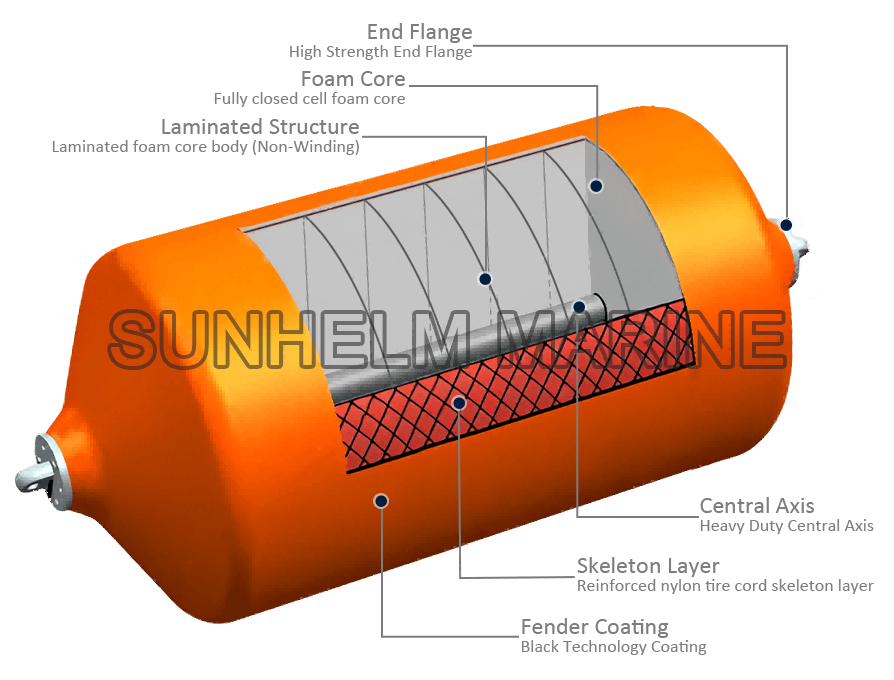

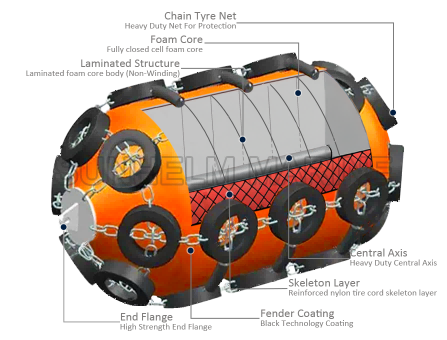

Foam Fender Construction

Foam Buoys Type

SunHelm manufacture in all types marine buoys and provide customized buoys solutions.

International Leading Foam Filled Fender Manufacturer

SunHelm Marine Co., Ltd. is a Chinese manufacturer specializing in maritime products. SunHelm Marine currently has several large-scale modern factories and R&D centers. SunHelm Marine mainly produces pneumatic fenders, marine rubber fenders, foam fenders, hydro-pneumatic fenders, marine airbags, marine salvage airbag, caisson moving airbags and other products.

Based on ship industry chain, SunHelm Marine has expanded its market layout, main business involves ship mooring and berthing, marine engineering, port construction and other fields. SunHelm provides customers with systematic, comprehensive and creative services.

After nearly 20 years of development, product and technology applications have covered more than 80 countries and regions in 7 continents, NANHAI became the well-known brand in the world.

Our Products

We are in the business of developing high performance marine rubber protections. According to 20 years researching and developing, SunHelm Marine has abundant experiences in custom designing marine fenders and airbags to meet specific application needs. We are pride with ourselves on our quality and stand behind our products.

YOU GOT QUESTIONS,

WE GET THE ANSWERS YOU NEED

We commitment that we will try our best to solve all the questions for our customer. We welcome and valued your advice to us. We are not only your supplier but also your key of success and your partner of business.