Ship Launching Airbag

The most cost-effective safe ship launching method. High-quality wound multi-layer rubber airbag.

Beyond ISO14409 International Standard.

Super high capacity performance and burst pressure.

Superior performance in harsh environments

Every detail of SunHelm ship launching airbag is paid highly attention.

Original Ultra-High Pressure Airbag (Independent R&D).

Ship launching airbags Introduction

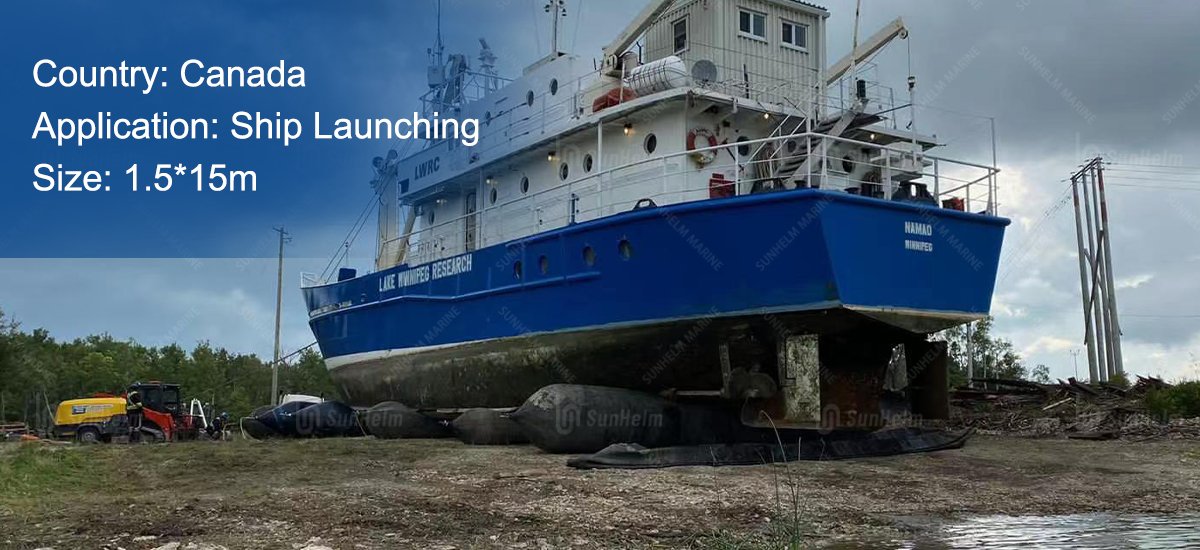

Ship launching airbags are the current ship launching program with the least cost and risk. It overcomes the shortcomings of fixed track launching and provides convenience for ship repair. At present, it is mostly used for the launch of small and medium-sized ships, and the productivity of shipbuilding and ship repairing in small and medium-sized shipyards is limited. Help companies in the shipbuilding and maritime industries save energy, time, workload and investment.

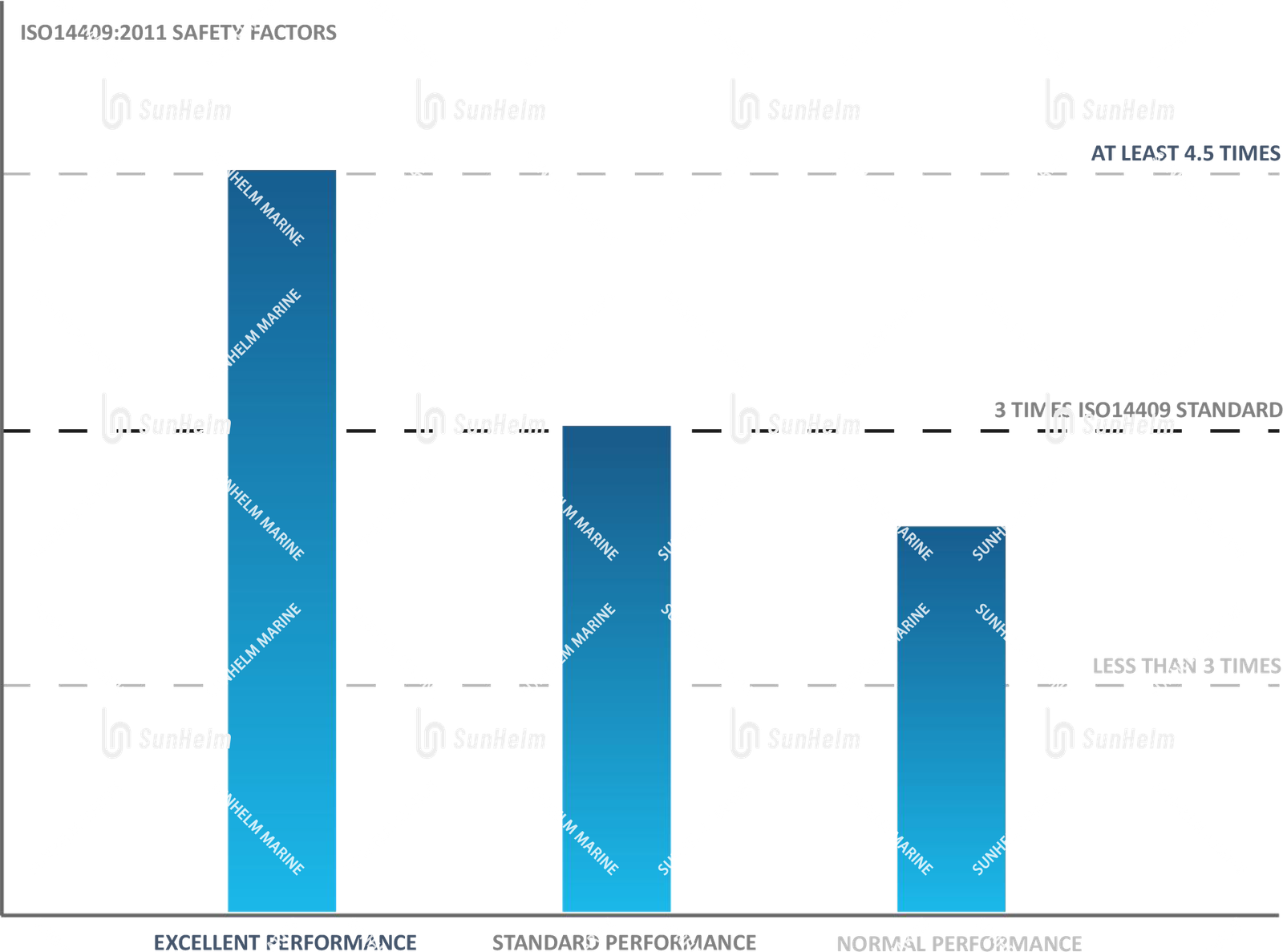

The Reason named SunHelm Ship Launching Airbag as "Defender", because of high performance in ship launching, Various performance indicators beyond international standard. Protect ship launching safety fully. Safety indicators highest reach 4.5-5 Times than international standard.SunHelm's ship launching airbag uses a cross-wound process, which can withstand greater impact. We use 100% high-quality natural rubber, which is more durable. The service life is more than 6 years, and other Chinese factories mostly use synthetic rubber.To exceed the performance of ISO14409 standard

Safety factor is the embodiment of comprehensive performance of ship launching airbag, it is an important factor to ensure the safe launching of ships. The safety factor of ship launching airbags depends on three important factors: material, design and production craft. At present, the safety factor of ship launching airbags from SUNHELM has reached at least 4.5 times in an all-round way, exceeding ISO14409 by 1.5 times.

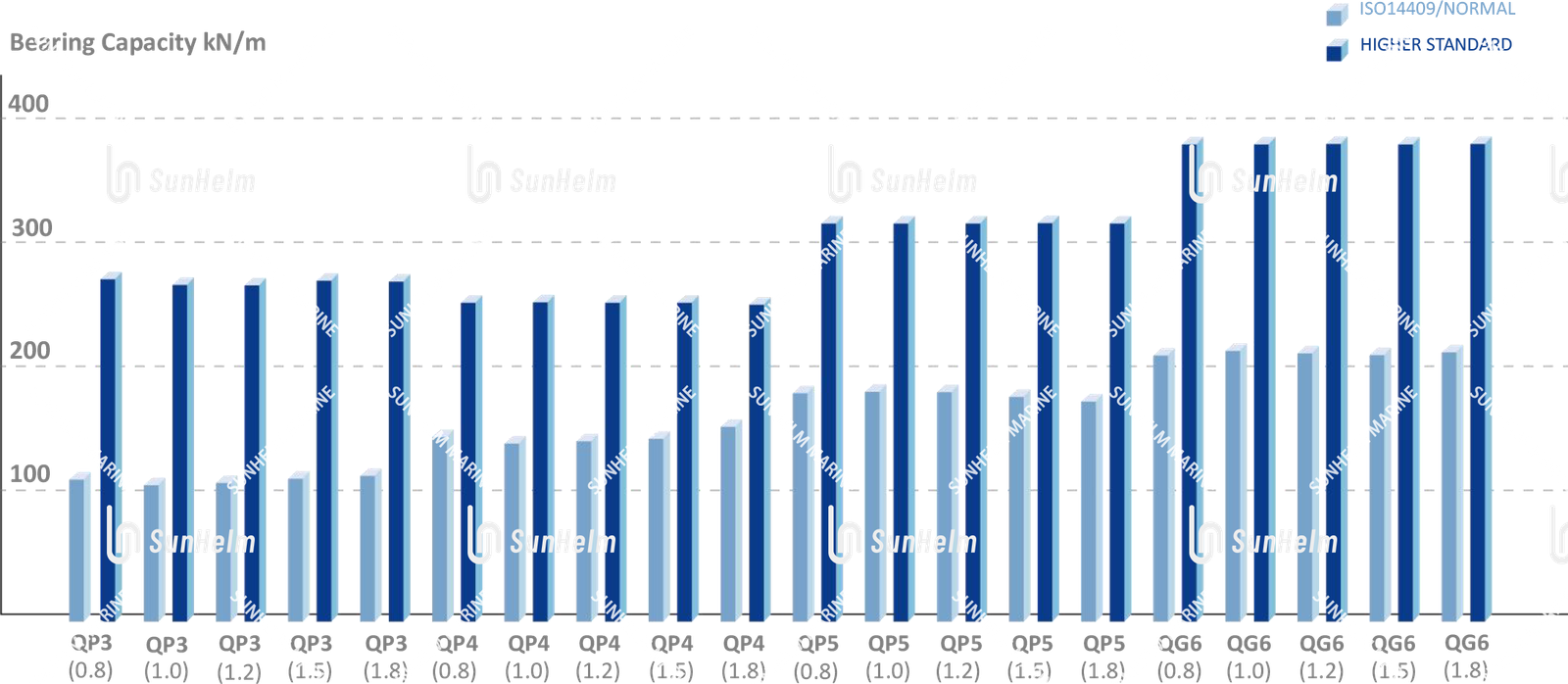

Excellent bearing capacity performance

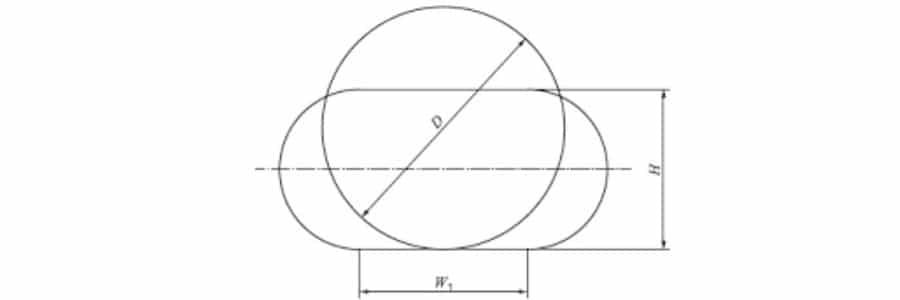

Bearing capacity definition: When compress deformation reaches 70%, and the inner pressure reach the rated working pressure,Pe. (Unit:kN/m) The core of bearing capacity is to test the pressure that airbag can bear during compression. The stronger bearing capacity,reflect stronger safety and stability of airbag.

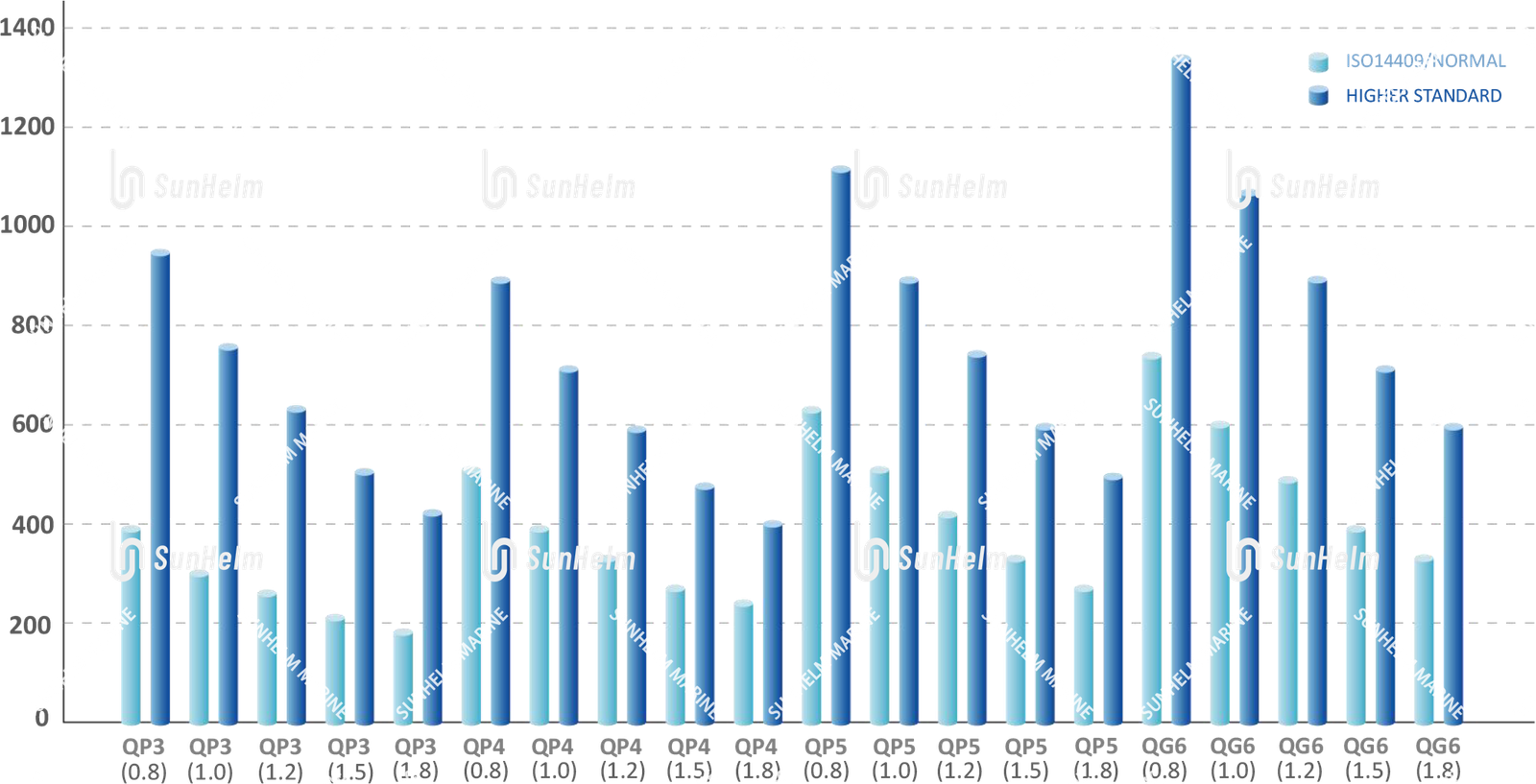

Super high burst pressure

Burst Test Definition: Airbags shall be tested to the minimum burst pressure as specified in table 2. Fill the airbag with water until the airbag burst. The water pressure at the time of bursting shall equal or be more than the value specified in table 2 (ISO14409 Required).

Ship launching airbags in harsh environments

In order to adapt to the harsh climate of Antarctica,SunHelm R&D team upgraded the material and process of the airbag, and cooperated with the Brazilian scientific research station to successfully complete the construction of the scientific research station. So far, the sales network of SunHelm products has covered seven continents in the world.

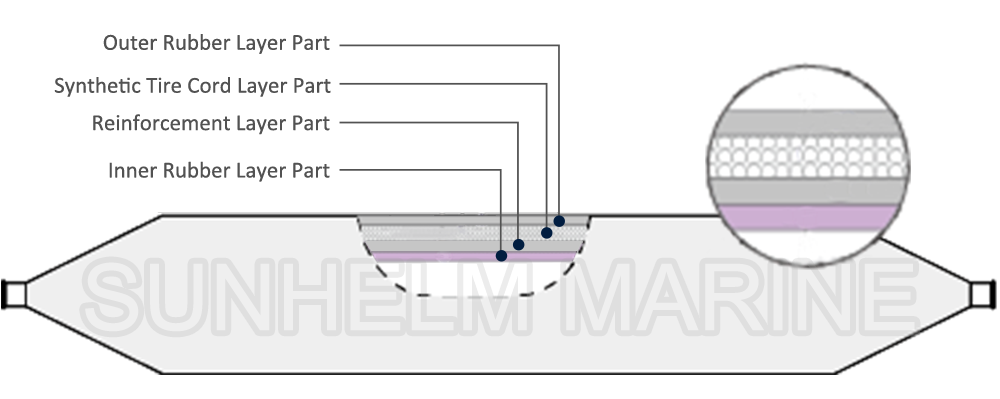

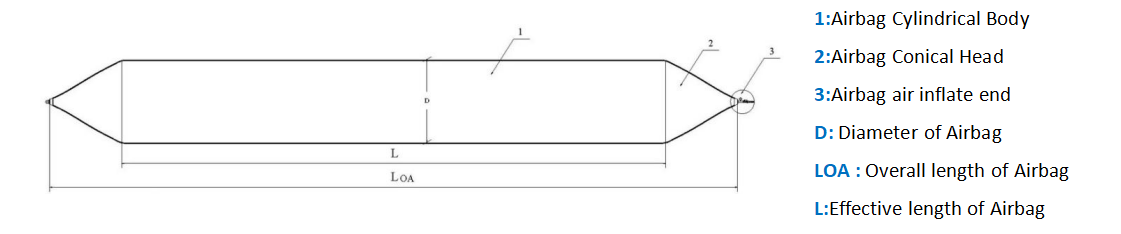

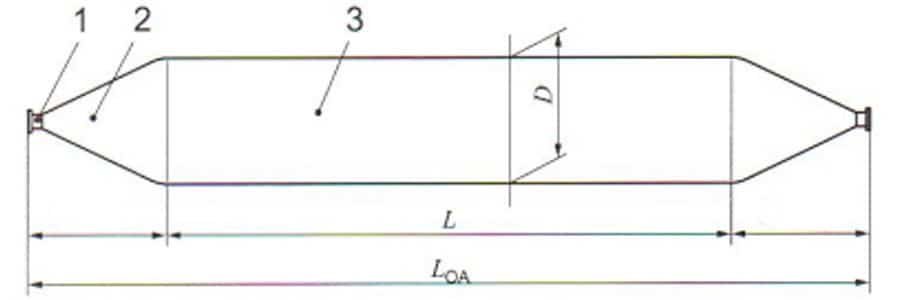

Ship launching airbags Construction

Outer Rubber Layer Part

I Mechanical protection (Friction) I Chemical Resistance (Environment) I Energy dissipation

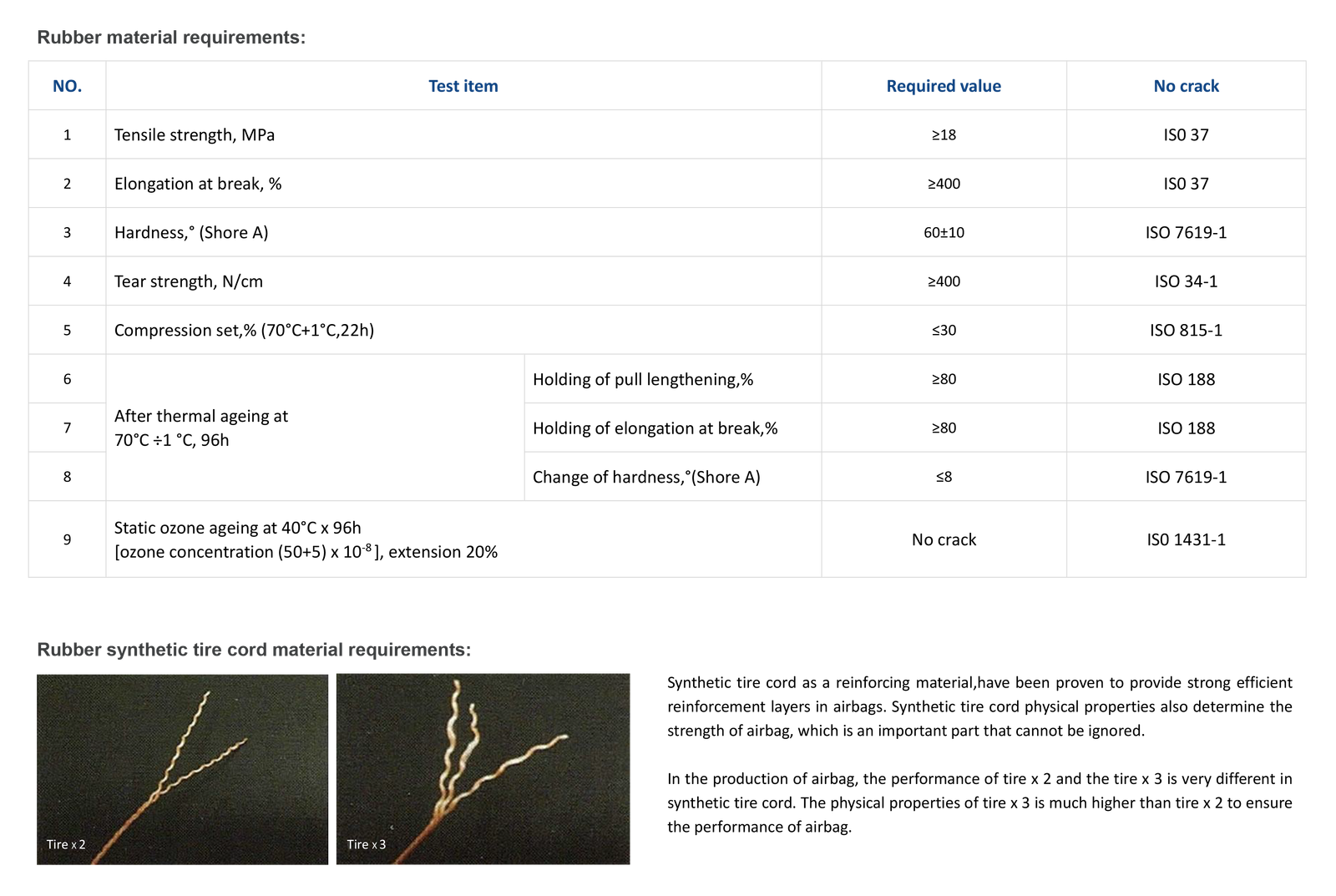

Synthetic Tire Cord Layer Part

I Carry load of membrane force I keep the geometry stable

Rubber Matrix Part

I Adhesion to reinforcement material I Distance layer of fabric plies I Shearing force loading

Air Tightness Layer Part

I Strengthen air tightness I Reinforces rubber & tire cord plies

Inner Rubber Layer Part

I Pressure transfer I Ensure air tightness I Provides chemical resistance

Step 1: Twine sealing tape on Reducing Joint.

Step 2: Reducing Joint connect Tee Coupling,seal with sealing tape.

Step 3: Ball Valve connect to Tee Coupling,seal with sealing tape.

Step 4: Quick Connector A connect Ball Valve,seal with sealing tape.

Step 5: Install Pressure Gauge to Tee Coupling.

Step 6: Quick Connectors B connect with Hose Fitting.With sealing tape.

Step 7: Quick connectors B connect Quick Connector A.

Step 8: Hose Fitting connect with inflated soft rope seal with Hoop.Start inflating.

We will provide you with the best quality products and the most competitive prices!

Want to ship quickly?

No problem!

info@sunhelmmarine.com

+86 (0)531 88255160

WhatsApp: +8615668327389

Ship launching airbags Performance

Airbag Layers (Layers) | Diameter (D) (Meter) | Operating Pressure (MPa) | Operating Height (m) | Bearing Capacity Each Meter (Ton/m) | ||||

|

|

| 0.4*D | 0.5*D | 0.6*D | 0.4*D | 0.5*D | 0.6*D |

3 Layers | 0.8 | 0.20 | 0.32 | 0.40 | 0.48 | 15.1 | 12.6 | 10.0 |

| 1 | 0.16 | 0.40 | 0.50 | 0.60 | 15.1 | 12.6 | 10.2 |

| 1.2 | 0.14 | 0.48 | 0.60 | 0.72 | 15.8 | 13.2 | 10.6 |

| 1.5 | 0.11 | 0.60 | 0.75 | 0.90 | 15.5 | 13.0 | 10.4 |

4 Layers | 0.8 | 0.19 | 0.32 | 0.40 | 0.48 | 14.3 | 11.9 | 9.5 |

| 1 | 0.15 | 0.40 | 0.50 | 0.60 | 14.1 | 11.8 | 9.4 |

| 1.2 | 0.13 | 0.48 | 0.60 | 0.72 | 14.7 | 12.2 | 9.8 |

| 1.5 | 0.10 | 0.60 | 0.75 | 0.90 | 14.1 | 11.8 | 9.4 |

5 Layers | 0.8 | 0.24 | 0.32 | 0.40 | 0.48 | 18.1 | 15.1 | 12.1 |

| 1 | 0.19 | 0.40 | 0.50 | 0.60 | 17.9 | 14.9 | 11.9 |

| 1.2 | 0.16 | 0.48 | 0.60 | 0.72 | 18.1 | 15.1 | 12.1 |

| 1.5 | 0.13 | 0.60 | 0.75 | 0.90 | 18.4 | 15.3 | 12.2 |

| 1.8 | 0.10 | 0.72 | 0.90 | 1.08 | 17.0 | 14.1 | 11.3 |

6 Layers | 1 | 0.24 | 0.40 | 0.50 | 0.60 | 22.6 | 18.8 | 15.1 |

| 1.2 | 0.20 | 0.48 | 0.60 | 0.72 | 22.6 | 18.8 | 15.1 |

| 1.5 | 0.16 | 0.60 | 0.75 | 0.90 | 22.6 | 18.8 | 15.1 |

| 1.8 | 0.13 | 0.72 | 0.90 | 1.08 | 22.0 | 18.4 | 14.7 |

| 2 | 0.12 | 0.80 | 1.00 | 1.20 | 22.6 | 18.8 | 15.1 |

7 Layers | 1 | 0.27 | 0.40 | 0.50 | 0.60 | 25.4 | 21.2 | 17.0 |

| 1.2 | 0.23 | 0.48 | 0.60 | 0.72 | 26.0 | 21.7 | 17.3 |

| 1.5 | 0.18 | 0.60 | 0.75 | 0.90 | 25.4 | 21.2 | 17.0 |

| 1.8 | 0.15 | 0.72 | 0.90 | 1.08 | 25.4 | 21.2 | 17.0 |

| 2 | 0.14 | 0.80 | 1.00 | 1.20 | 26.4 | 22.0 | 17.6 |

8 Layers | 1 | 0.31 | 0.40 | 0.50 | 0.60 | 29.2 | 24.3 | 19.5 |

| 1.2 | 0.26 | 0.48 | 0.60 | 0.72 | 29.4 | 24.5 | 19.6 |

| 1.5 | 0.20 | 0.60 | 0.75 | 0.90 | 28.3 | 23.6 | 18.8 |

| 1.8 | 0.17 | 0.72 | 0.90 | 1.08 | 28.8 | 24.0 | 19.2 |

| 2 | 0.15 | 0.80 | 1.00 | 1.20 | 28.3 | 23.6 | 18.8 |

| 2.5 | 0.12 | 1.00 | 1.25 | 1.50 | 28.3 | 23.6 | 18.8 |

What can

we do for you?

Find us to know more

Find us to know more

Find us to know more

Sunhelm has independently developed and produced pneumatic rubber fenders for 15 years. The production technology is mature, the technical research and development team is perfect, and the materials and production methods are constantly updated. It is already a leading manufacturer and supplier of pneumatic fenders in China.

Many export countriesSunhelm has been deeply involved in the international market, and yokohama pneumatic fenders have been sold to 27 countries around the world including Russia, Brazil, Indonesia, Malaysia, Germany, Panama, and the United Arab Emirates. The customer complaint rate is only 1%.

Higher safety factorSunhelm’s pneumatic Yokohama fender fully meets the ISO17357 standard, uses a stronger cord layer, and has a safety factor of 7 times. You can buy it more at ease.

Find us to know more

Bee Nest Airbag

Bee Nest Puncture-resistance airbag is a unique patented product independently developed by SunHelm own R&D teams. On the basis of traditional airbags, The Bee Nest puncture-resistance airbags add layer of high-strength anti-puncture composite material, which can effectively prevent accidental scratches and punctures caused sharp objects, improved the service life of the product significantly.

Puncturing prevention. High-density steel cord form a protective layer, overcomes the drawback of rubber easily puncture.

Scratching prevention. High-density steel cord layer prevents accidental scratches efficiently.

Less layers ,easy for operation.No need to increase the thickness of the airbag to improve the puncture-resistance performance.

Get More